There are two main classifications for loading mechanisms: ramps and dock levelers.

Loading Ramps

Incorporating seamless integration into concrete, our ramps eliminate the need for extra space. They harness state-of-the-art hydraulic technology and a meticulously crafted design, rendering them an exceptionally practical solution. Consequently, they not only reduce loading times but also bolster overall work efficiency. Moreover, their extensive range of motion ensures compatibility with a diverse range of vehicle types for both loading and unloading operations. To maximize user-friendliness and prevent forklift slippage, we’ve optimized hydraulic and electrical compatibility, thanks to the tear-patterned sheet.

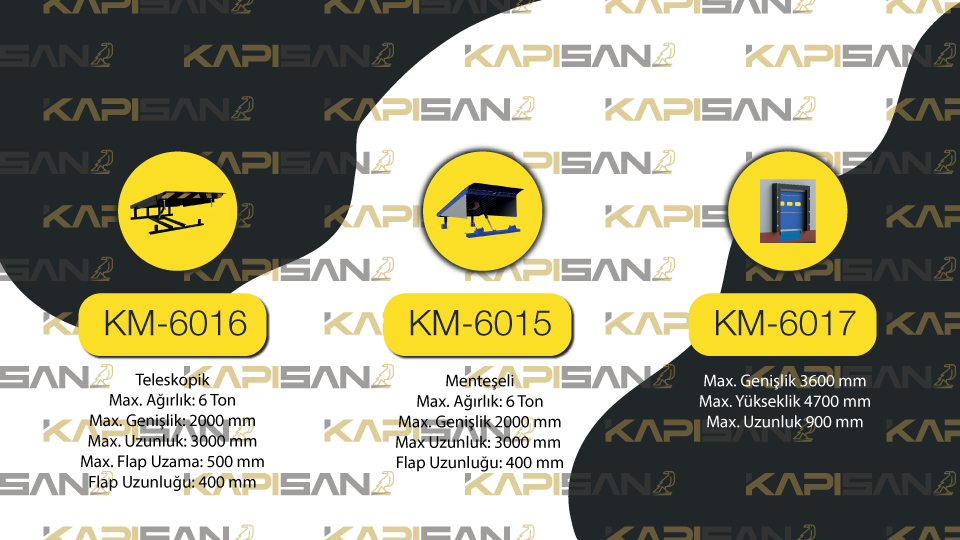

Furthermore, the design of our ramps offers precise level adjustments, tailored to the specific height of each vehicle, guaranteeing adaptability in various situations. When it comes to loading ramp options, we provide two distinct models: the hinged and the telescopic. The telescopic loading ramps, in particular, extend their flaps when the hinged ramp’s flaps are insufficient, making them an excellent choice, especially for container loading tasks. With hydraulic flaps ranging from 600 mm to 1000 mm in width and boasting a thickness of 12/13 mm, these ramps provide the optimal solution for container loading.

Loading Ramps

Our ramps play a pivotal role in optimizing loading systems, thus significantly enhancing efficiency during the loading and unloading operations in warehouse or depot buildings. They serve as watertight bridges, seamlessly connecting the building and vehicle bodies, effectively blocking the transfer of heat and air, all thanks to their high-quality materials.

In our product lineup, we offer two distinct types: the leaf type and the inflatable type.

The leaf type employs a scissor system and is equipped with self-protection mechanisms, ensuring an extra layer of safety against potential vehicle collisions. In stark contrast, the inflatable type employs a fan-driven inflation process, creating a secure enclosure around the vehicle. Importantly, the inflatable type excels in its ability to prevent the transfer of both air and heat, providing an exceptional solution for controlling environmental factors.

In essence, our ramps not only enhance efficiency but also contribute to maintaining optimal conditions within your loading and unloading processes, making them indispensable assets for your warehouse or depot operations.

Loading Ramps

We have successfully incorporated loading ramps into the goods loading and unloading processes at factories and logistics warehouses. These loading ramps streamline the process once heavy vehicles such as trucks have arrived and docked in the designated area.

Our loading ramps come in various sizes, which can be chosen based on factors like warehouse height, vehicle width, and other relevant variables. We also offer specialized production options to tailor our ramps to unique vehicle and warehouse height requirements, in addition to our standard dimensions.

You can select loading ramps in different sizes, considering factors like warehouse height and vehicle width, among other variables. We also offer specialized production to cater to unique vehicle and warehouse height requirements, in addition to our standard dimensions.

Logistics centers and warehouses commonly utilize loading dock seals. These seals serve to alleviate the effects of inclement outdoor conditions on stock areas within these facilities.

The flexible rubber flaps and scissor systems of these loading dock seals enable quick and efficient loading and unloading processes. Industries such as textiles, food, and pharmaceuticals place a high priority on factors like hygiene, temperature control, and humidity levels.

Since 1983, as Kapısan we have been an expert in providing security for properties and businesses. With our team of expert engineers and in-house production, we continue to push the boundaries of rolling shutter technology. Contact us today to discover what rolling shutters can do for your business.